Description

Wema Tachometer with Hourmeter combines a 0-4k or 0-8k tachometer with an LCD hour meter.

Please note: The 3k tachometer is special order only (available with MOQ of 25).

Two versions are stock items; the 4k & 8k. Please contact us for further information.

(some pictures not of actual display)

The tachometer with Hourmeter should only be installed by a qualified marine electrician.

INSTALLATION INSTRUCTIONS AND LEARN MORE ABOUT TACHOMETERS

Specifications

- Tachometer with Hourmeter

- 0-4000 RPM or 0-8000 RPM

- Built in LCD Hourmeter

- 85mm (3 3/8") diameter gauge

- 12v or 24v (with resistor)

- Marine grade IP67 waterproof

- 2 & 4 cycle signal output

- Square or sine wave

- Works with W terminal or inductive sensor

- Choice of face and bezel colours.

- Red or orange backlight

The choice of shipping options is calculated at the checkout.

The price and available shipping options will depend on your location as well as the size and weight of your order.

If you choose 'free delivery' or some Royal Mail services, the order may not be trackable for the duration of the journey and only show tracking events when the order is shipped and when it is delivered.

We aim to dispatch all morning (GMT) orders the same day and all orders received afternoon or at weekends the following business day.

Once your order has shipped you will be notified by email.

To supply a replacement fuel or water sender we just need to know:

-

What resistance is it?

-

How long is it?

-

How many wires does it have?

- What type of tank is it being fitted into?

- What is the Wema product code?

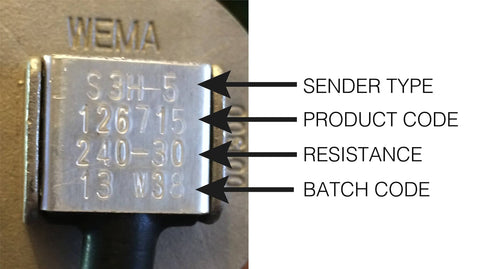

If your sender has information stamped on the head then we can identify your sender from the product code:

[Please note: the code 001300 refers to the S3 head and the code 001306 / 001305 refers to the S5 sender head]

Do you have an S3 or S5 sender?

The S3 sender has a screw in head with a 1.25" BSP thread like this:

[NOTE: A 1.25" BSP (British Standard Pipe) thread will actually measure larger than 1.25 inches when measured with a tape measure. This is because a BSP measurement refers to the internal bore of a pipe (for accurate flow rate) and not the outside of the thread.]

The S5 sender has a bolt down head with 5 holes like this:

[NOTE: The 5-hole drill pattern in the top of an S5 sender head is a standard SAE-5-hole pattern.]

If you have a sender that is not an S3 or S5 then please click here

What resistance is your current sender and gauge?

The sender and gauge must have the same resistance values or the gauge will read incorrectly.

You can either test the gauge or the sender to find this out.

To test the sender:-

Disconnect the two wires on top of the sender.

-

Remove the sender from the tank.

-

Connect the wires on the sender to a multimeter.

-

Set the multimeter to resistance [Ω ohms]

-

Move the float to the top of the sender and take a reading on the multimeter:

-

At the top of the sender (full) the resistance should be:

-

European specification - 190 ohms

-

American specification - 30 ohms

-

Move the float to the bottom of the sender and take a second reading:

-

At the bottom of the sender (empty) the resistance should be:

-

European specification - 0 ohms

-

American specification - 240 ohms

If you have access to the wires on the back of the gauge;

-

Power the gauge off

-

Disconnect the black wire (sender)

-

Power the gauge on

-

If it's an American gauge the needle will show EMPTY

-

Touch the black wire to earth, the needle will go to FULL

-

If it's a European gauge the needle will show FULL

-

Touch the black wire to earth, the needle will go to EMPTY

If you don't have access to the back of the gauge;

-

Disconnect the two wires in the loom that attach to the sender.

-

If it's an American gauge the needle will show EMPTY

-

If it's a European gauge the needle will show FULL

Length?

To measure an S3 or S3H sender (with screw in head) measure from the top of the thread to the bottom of the stem.

To measure an S5 sender (with bolt down head) measure from the underside of the flange to the bottom of the stem

How many wires?

If your S5 or S3 sender has 2 wires then it is a standard resistance sender.

If your S5 or S3 sender has 3 or 4 wires then it is either a 0-5v, 0-10v sender or it has a high/low level alarm.

If you have a 3 or 4 wire sender then please contact us before ordering.

If your sender has a high or low level alarm we will need to know if the switch is normally off (when the tank is empty), turning on when the tank is full or normally on, turning off when the tank is full. We will also need to know how far from the top or bottom of the sender you would like the alarm switch to be.

Tank Contents?

For fuel or water then you can fit the maximum length of sender for your tank.

For a black water holding tank we recommend leaving at least 50mm from the bottom of the tank regardless of the material the tank is made from.

If you tank does not contain fuel, fresh water, grey water or black water then please contact us for more specific information. For very thick liquids like oil or grease we may need to know the viscosity.

Wema Sender Identification Chart

(click here for larger view)